Table of Contents

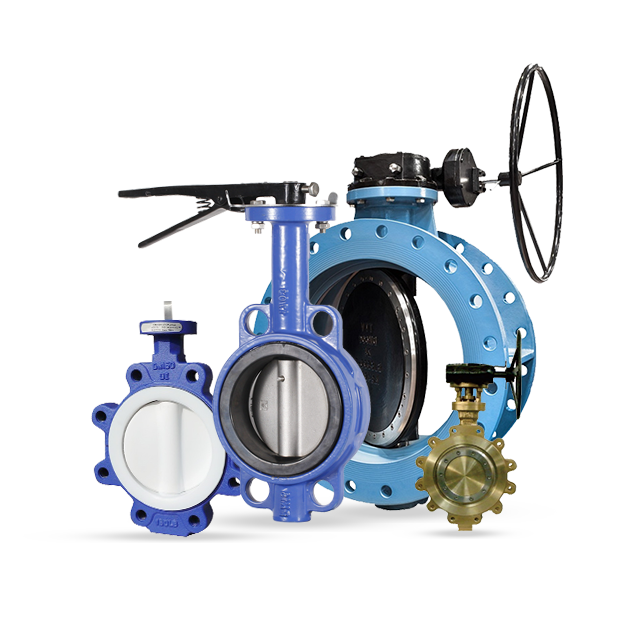

What is a Butterfly Valve?

How Does a Butterfly Valve Work?

Butterfly valves function using a simple mechanism. A rotatable disk or “butterfly” is mounted on a spindle within the valve body, which spans across the pipe’s diameter. The disk swings into the fluid flow (becoming parallel) to allow passage and rotates perpendicularly to stop the fluid flow, hence the name “butterfly.”

When we consider different sizes, such as a 4 inch butterfly valve or a 6 inch butterfly valve, the primary difference lies in the application scope. Regardless of size, the operational principle remains the same, allowing butterfly valves to offer effective control over fluid flow in various situations.

How Are Butterfly Valves Different From Other Valves?

While butterfly valves may seem similar to other valve types, like ball or gate valves, key differences exist. Butterfly valves are typically more cost-effective and lighter in weight due to their design simplicity. For instance, the materials needed for an 8 inch butterfly valve would be less than those required for an 8-inch gate valve. This makes butterfly valves easier to install and maintain.

Unlike other valves, butterfly valves offer less restriction to fluid flow when fully open, reducing pressure drop across the valve. However, they may not provide as tight a seal as some other valve types, making them less suitable for applications where a complete shut-off is required.

What Should You Consider When Choosing a Butterfly Valve?

When selecting a butterfly valve, considerations extend beyond merely deciding between a 6 inch butterfly valve and a 10-inch butterfly valve. Firstly, consider the nature of the fluid, its temperature, and pressure. Some butterfly valves may not perform well under high temperatures or corrosive fluids, so the valve material should be chosen accordingly.

The required flow control level is another critical consideration. While butterfly valves are excellent for regulating flow, they might not be the best choice if a complete shut-off is necessary. The operating environment also influences the valve type selection, as manual operation may not be suitable in hard-to-reach places or hazardous environments.

Butterfly Valve Installation and Maintenance

Installing a butterfly valve correctly is crucial for its effective functioning. Whether it’s a small 4 inch butterfly valve or a larger 10 inch butterfly valve, proper installation ensures optimal performance. It’s important to consider the pipeline’s alignment, and the valve should be installed in a way that facilitates easy maintenance access.

Maintenance of butterfly valves usually involves regular inspection for leaks and wear, with periodic replacement of the seal or the entire disk if necessary. Lubricating the valve’s moving parts can also prolong its lifespan. Always remember that regular maintenance can significantly reduce the risk of failure and extend the valve’s operational life.

In conclusion, butterfly valves are versatile devices for fluid flow regulation, offering benefits of simplicity, cost-effectiveness, and easy maintenance. Whether you need a 4-inch, 6-inch, 8-inch, or 10-inch butterfly valve, understanding their working principle, differences from other valves, selection considerations, and maintenance procedures will help ensure their effective utilization in your applications.

Conclusion

Butterfly valves are an important component in many industrial applications that require fluid flow control. Compared to other types of valves, butterfly valves are versatile, cost-effective, and simple to maintain. From 4-inch butterfly valves to large 10-inch butterfly valves, they provide efficient fluid flow regulation for a wide range of industries. Understanding how butterfly valves work, how they differ from other valves, selection considerations and maintenance procedures is critical to maximising their efficiency and service life. So whether you’re operating a small project or managing a large industrial system, careful consideration and application of butterfly valves can improve your operational efficiency and ultimately contribute to the success of your project. Please contact us if you need butterfly valves.